To understand blowdown loss, you first have to know what blowdown means and why it's necessary. When water evaporates from a cooling tower, solids that were in that water remain in the tank, being redistributed into the existing water. Before the concentration of these solids becomes too high, some of this water is removed and replaced with fresh water. This process is called blowdown, and blowdown loss is the amount of water lost during the blowdown process in your cooling tower.

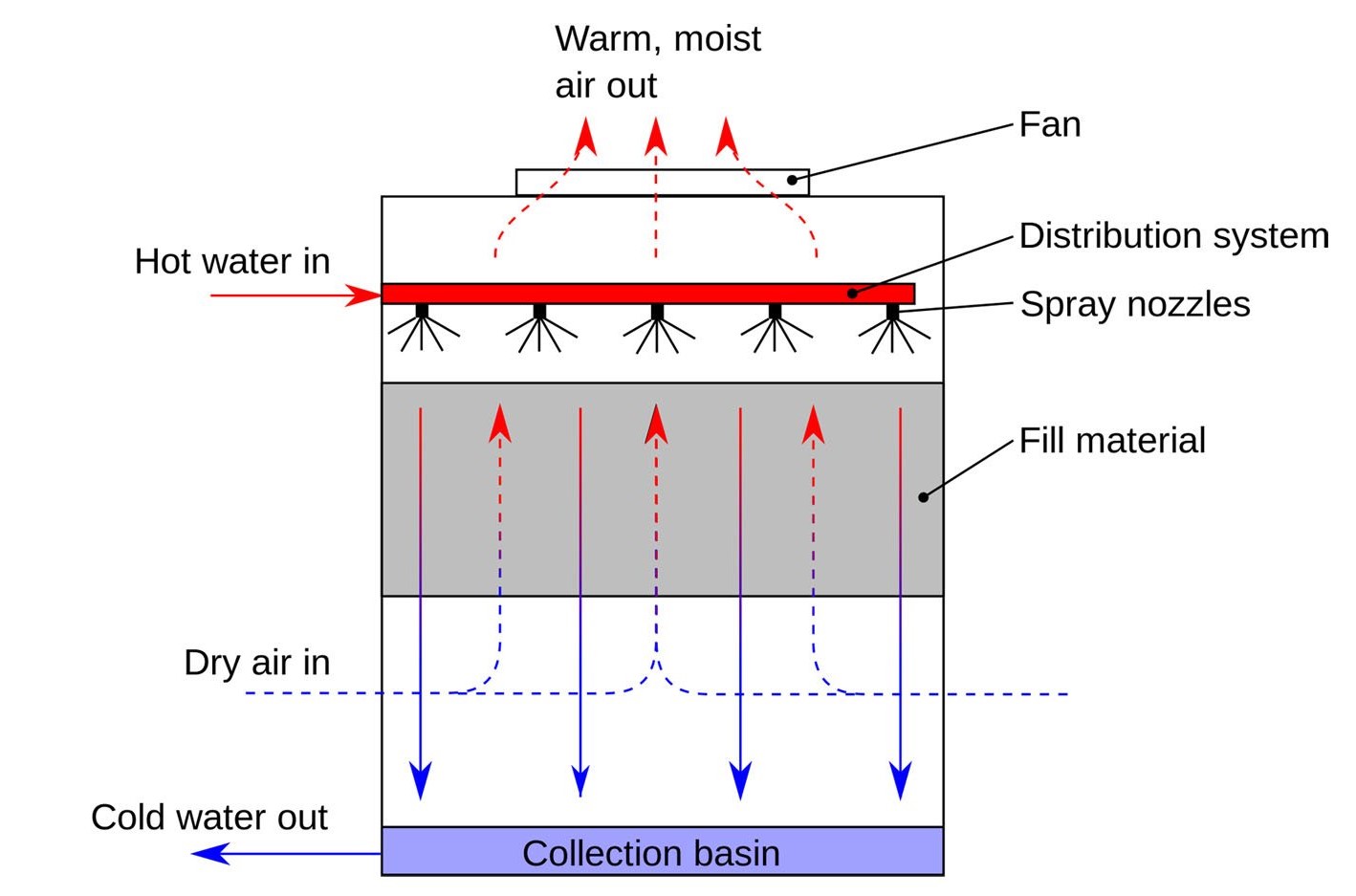

All cooling towers work on the same physical principles regardless of which water cooling towers manufacturers built them: Mass falls, but heat rises. You pump hot water to the top of the tower and let it fall down the interior.

Some of the water evaporates, and the resulting vapor carries off heat, allowing you to use the remaining water for future cooling. This is called an open circuit cooling tower, where a closed-circuit tower uses two cooling loops so that the processed water you use to cool never reaches the atmosphere. Both systems work very effectively in the right situations

.

Anyone who has ever simmered a sauce knows that evaporation means concentration. Water vapor being lighter, floats away, leaving all the heavier compounds like minerals behind. If too much water evaporates, you end up with more minerals than the remaining water can carry. The extra minerals thus fall out of the water to deposit themselves on any nearby surfaces producing scale. Left untreated, this scale builds up inside pipes and can even block them. With little or no coolant getting to the hottest part of the system, scale buildup can very rapidly bring any system to its knees.

The easiest way to deal with scale is with blowdown. The more water you replace with make-up water, the fewer minerals you reintroduce to the system and the less buildup you get.

The problem is that this uses tremendous amounts of water and purges large amounts of potentially toxic wastewater into the environment.

Another option is to use a scale inhibitor treatment in your cooling water. These chemical additives raise the saturation point of the water so it can carry a higher concentration of minerals without worrying about scale deposits. Using the cooling water blowdown formula, you can calculate how much fresh blowdown water a system will need for a given concentration of scale inhibitor treatment.

Thus, using the right scale inhibitor to reduce blowdown requirements not only saves you both money and energy, it also reduces the environmental impact of your installation.

For more about the installation, repair, and maintenance of cooling towers by top cooling tower manufacturers, contact Delta Cooling today. We can help you find the best option for your needs, and all our installations come complete with a 20-year warranty for your peace of mind.

From our low maintenance design to our manufacturing process to excellent customer service, we're sure you'll be pleased with our superior cooling towers, every step of the way. Get a quote