A cooling tower is a heat removal device that uses water to transfer process waste heat into the atmosphere. Likewise, an industrial cooling tower operates on the principle of removing heat from water by evaporating a small portion of water that is recirculated through the unit.

The mixing of warm water and cooler air releases latent heat of vaporization, causing the water to cool. If you are ever looking down from a high-rise building, you might notice a square unit, with fans on top of it, on the buildings below. That's a water cooling tower.

No one wants to stay in a building with bad air conditioning—at least not for too long. On the other hand, buildings with excellent cooling make you want to return, even if it’s just to enjoy the air. That’s thanks, in large part, to the continued modernization and innovation of the commercial cooling tower system.

A water cooling tower is used to cool water and is a huge heat exchanger, expelling building heat into the atmosphere and returning colder water to the chiller. A water cooling tower receives warm water from a chiller.

This warm water is known as condenser water because it gets heat in the condenser of the chiller. The chiller is typically at a lower level, like in a basement. The cooling tower’s role is to cool down the water, so it can return to the chiller to pick up more heat.

Air conditioning equipment and industrial processes can generate heat in the form of tons of hot water that needs to be cooled down. That’s where an industrial cooling tower comes in. Overheated water flows through the cooling tower where it’s recirculated and exposed to cool, dry air. Heat leaves the recirculating cooling tower water through evaporation.

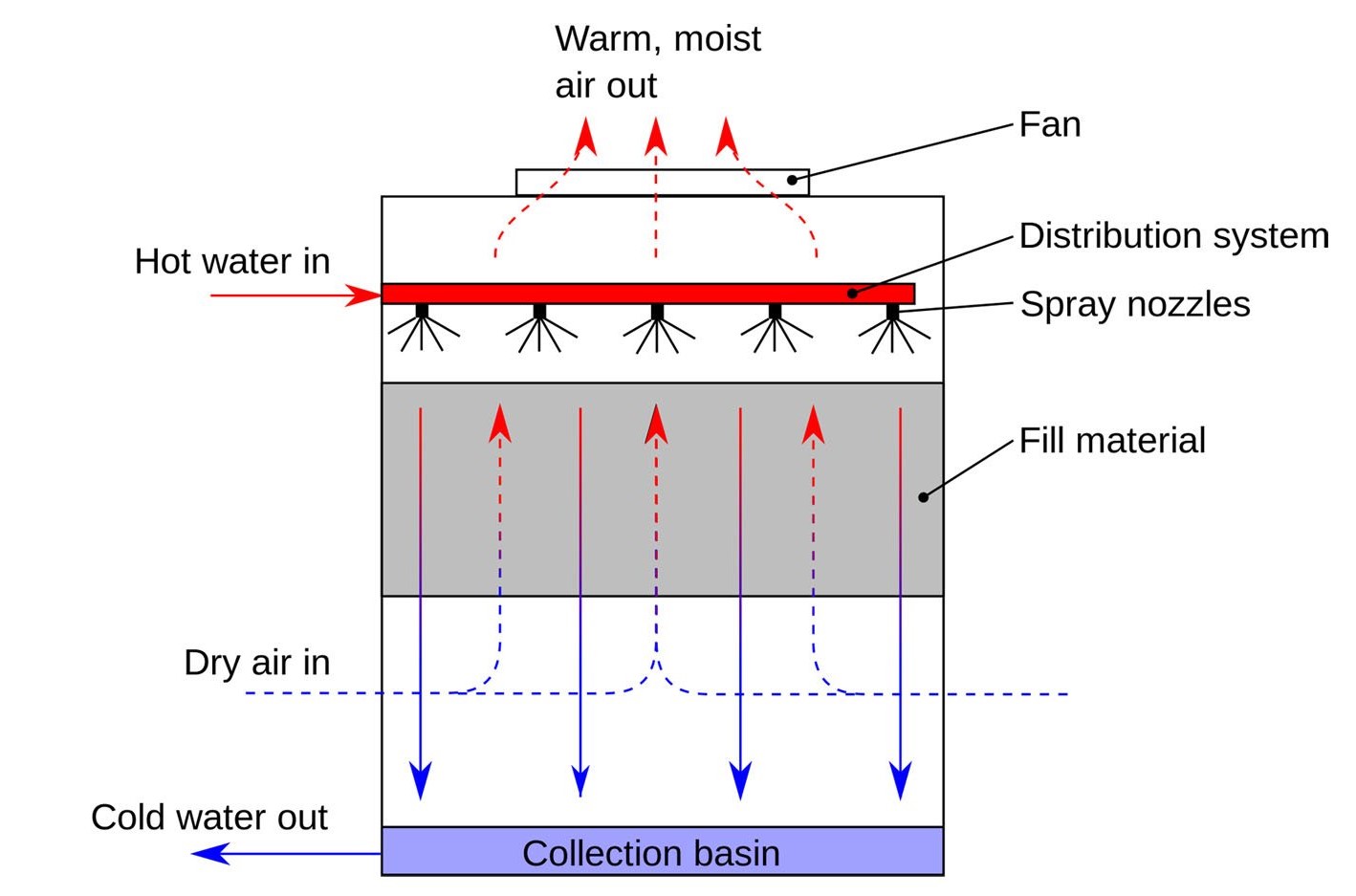

This is called evaporative cooling. The colder water then reenters the air conditioning equipment or process to cool that equipment down, and the cooling cycle repeats over and over again. When the warm condenser goes into the cooling tower, the water is passed through some nozzles which spray the water into small droplets across the fill, which increases the surface area of water and allows for better heat loss thru greater evaporation.

The purpose of the fan on top of the water cooling tower is to bring in air from the bottom of the tower and move it up and out in the opposite direction of the warm condenser water at the top of the unit. The air will carry the heat by evaporating water from the cooling tower into the atmosphere.

An industrial cooling tower is a critical component of many refrigeration systems and can be found in industries such as power plants, chemical processing, steel mills, and many manufacturing companies where process cooling is necessary. Also, a commercial cooling tower can be used to provide comfort-cooling for large commercial buildings like airports, schools, hospitals, or hotels.

An industrial cooling tower can be larger than an HVAC system and is used to remove the heat absorbed in the circulating cooling water systems used in power plants, petroleum refineries, petrochemical plants, natural gas processing plants, food processing plants, and other industrial facilities.

With the increased rate of the population all over the world, there has been a huge rise in the rate of needs and requirements by the world for manufactured products. This has forced the industrial sector to manufacture more and more products every day, which generates more manufacturing process heat.

The machines and processes of industries that generate tremendous amounts of heat must be continuously cooled so that those machines can continue to operate efficiently. The most efficient, effective, and least expensive solution to removing this heat is the installation of an industrial cooling tower.

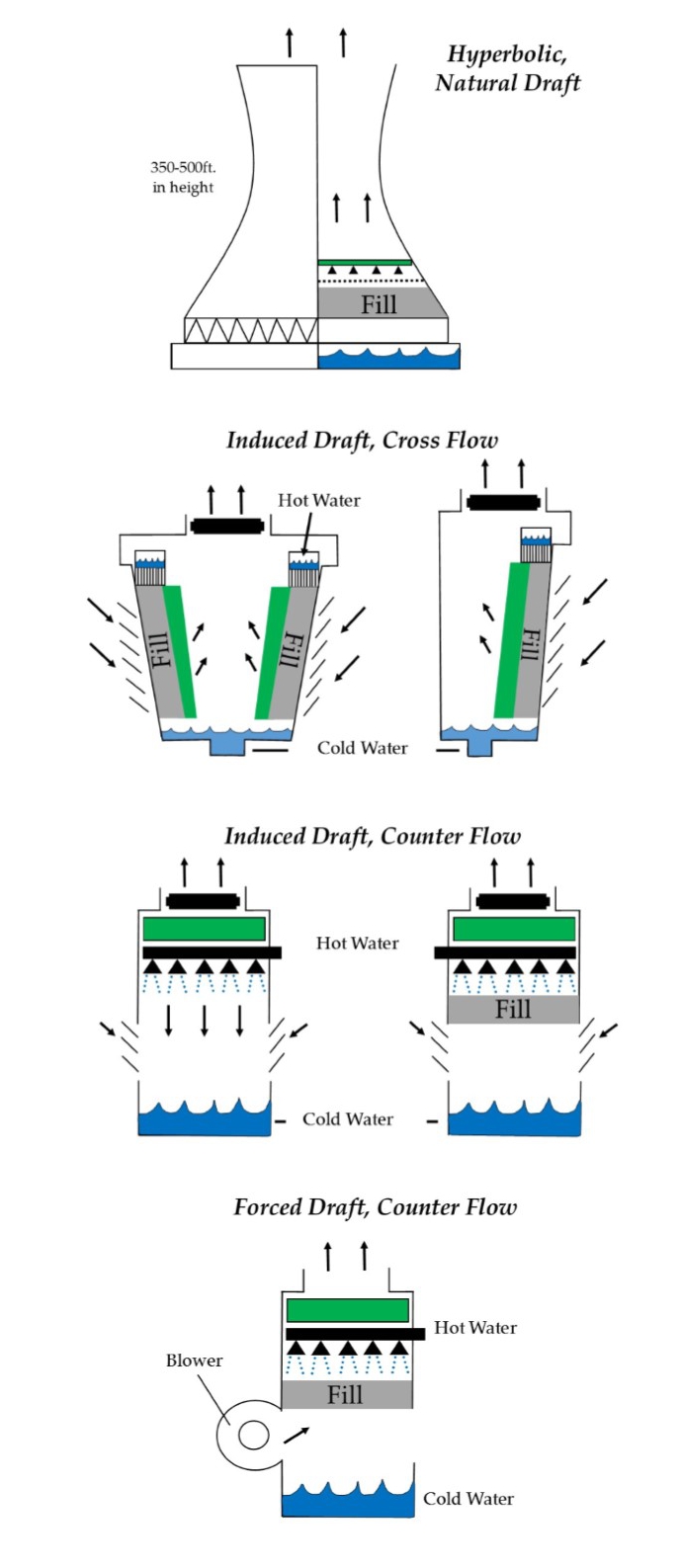

Cooling tower systems are often vital to industrial processes. These tall, open-topped, cylindrical structures are responsible for cooling water generated from industrial or HVAC comfort cooling airflow. The different types of cooling towers are identified by the classification of the draft (natural or mechanical) and by the direction of airflow (counter or cross).

are usually used for large power plants and industries with infinite cooling water flow. The tower operates by removing waste heat by way of rising hot air that is then released into the atmosphere. These towers are tall and have a hyperbolic shape to induce proper airflow.

These towers have air forced through the structure by a fan that circulates air through the tower. Common fans used in these towers include propeller fans and centrifugal fans. While Mechanical draft towers are more effective than natural draft towers, they consume more power and cost more to operate as a result.

have a design that allows the air to flow horizontally through the fill and the tower’s structure into an open plenum area. Hot water flows downward from distribution basins. However, fans and motor drive require weather-proofing against moisture which can lead to freezing making it less efficient.

have a design where the air moves upwards and the counter-current, with hot water, falls downward to cool the air. This allows for maximum performance out of each plan area and helps minimize pump head requirements. Also, a counterflow cooling tower system is less likely to ice up in cold weather conditions and can save energy in the long run. All Delta Cooling Towers are counterflow and all include these advantages.

are typically mounted with a fan at the top of the cooling tower, which allows hot air out and pulls air throughout. The high exiting air velocities reduce the chance of re-circulation. To avoid the entrapment of water droplets in the leaving stream air, drift eliminators are used. Induced draft towers are more efficient as they use 30% to up to 75% less energy compared to forced draft designs.

This cooling tower system is similar to induced draft, but the basic difference is that the air-moving fan is placed at the base of the cooling tower, which allows the air to blow through from the bottom. Their use is limited due to water distribution challenges, high horsepower fans, and the possibility of re-circulation.

Water-cooled systems are primarily made from three materials: Metal, fiberglass, and plastic. As you know, metal can rust and corrode, and whatever’s inside of it can begin to leak over time.

Water-cooled systems are primarily made from three materials: Metal, fiberglass, and plastic. As you know, metal can rust and corrode, and whatever’s inside of it can begin to leak over time.

To no surprise, a metal cooling tower only has an average shelf life of up to only 15 years and requires maintenance with epoxy paint, sealants, and more. That maintenance can lead to downtime for your business. This is why metal is now being replaced with better technology. Fiberglass cooling tower manufacturers, although providing a better alternative to metal, are still prone to cracks and wear which can lead to long-term higher maintenance costs.

An engineered plastic cooling tower is designed to stand up to wear and tear. It doesn’t rust or chip—and it can weather harsh environmental conditions. It also requires almost zero maintenance. High-density polyethylene (HDPE), a best-in-class engineered plastic used by Delta Cooling Systems, is seamless and resistant to environment-induced corrosion, unlike metal or fiberglass cooling towers. With a life expectancy of more than 20 years, you can install it once knowing you will not have to worry about it afterward.

Advancements in the manufacturing and design of today’s engineered plastic towers changed the use of cooling towers from a valuable support tool, to one of productivity and savings in the cost of a cooling tower. Factory-assembled commercial cooling towers became popular at the same time when engineered molded plastics became more desired over the galvanized metal models that once dominated the industry. There are many reasons why you might want to consider an engineered plastic cooling tower to reduce costs and better meet your process needs:

According to the Centers for Disease Control and Prevention (CDC), water cooling towers can be a breeding ground for Legionella bacteria, the microbes that cause Legionnaires’ disease. Here’s why: Bacteria thrive in warm, wet conditions, making watercooling towers an ideal environment.

As a result, people can get Legionnaire’s disease, which can cause pneumonia, when they breathe in water droplets dispensed from HVAC systems that contain Legionella bacteria. In fact, a 2017 study by the CDC found six Legionnaires’ outbreaks in New York City that resulted in 213 cases and 18 deaths. Three of those outbreaks were linked to cooling towers.

To address this public health concern and liability, companies are treating the water inside of their industrial cooling tower with antimicrobial substances that kill the bacteria. For other water treatment applications, an air stripper is often used. As another precaution, plastic cooling tower systems can be manufactured with antimicrobial resins built into the unit materials and components to provide an additional layer of defense against Legionella. Find out more about the anti-microbial product technology at Delta Cooling Towers.

With the increasing concerns about meeting green standards and improving ROI on capital equipment expenditures, there are some standards to consider.

With the increasing concerns about meeting green standards and improving ROI on capital equipment expenditures, there are some standards to consider.

A systematic approach to cooling tower greenness will improve sustainability, increase energy efficiency, add water conservation, and create a smaller carbon footprint; all while improving some cost ramifications involved in achieving such green goals. Businesses can save up to 40 percent on energy costs. While conventional cooling towers, often constructed with sheet metal cladding, are environmentally challenging and maintenance intensive, the alternative of using cooling towers with molded seamless plastic is immediately beneficial to both the environment and your bottom line.

Traditional metal towers, which last only a few years in many applications, encounter environmental and economic issues including increased chemical use, higher maintenance costs, replacement costs, and disposal requirements. Engineered HDPE plastic design cooling towers allow the most aggressive water treatment options available. This can allow users to run at higher cycles of concentration, thereby saving make-up water. This can save tens of thousands of gallons of water per year.

These water and chemical savings can be significant and help solve water issues as well as save on operating costs. Cooling towers of this counterflow design also keep water totally enclosed and free from sunlight, thereby lessening the occasion for biological growth, which requires less harsh water treatment chemicals. Get more details here about Delta’s sustainable technology and products.

Think of it this way: Cooling tower systems are essential to many businesses, which means looking for efficiencies in operations and products can help impact the bottom line. Water consumption can be a major operating expense, and cooling towers can recycle about 98% of the water used in process cooling or air conditioning. If the unit is made from plastic and uses water instead of air as a cooling method, business owners can anticipate reduced energy costs, little-to-no maintenance, and extended product longevity, compared to older, metal systems.

That’s a highly desirable scenario for any business to cut down on costs. Furthermore, many customers appreciate knowing that the businesses and industries that support communities are environmentally conscious and working toward sustainable practices. That may not be a money-saving factor, but it could boost consumer confidence. And that’s good for business, too.

As you can see, there’s a lot to learn about cooling tower systems. Not only do they perform a function many of us couldn’t live without (that’s air conditioning, of course), they’re highly technological and, yes, cool. Perhaps knowing more about cooling towers will give you a greater appreciation for cool air.

The approach is the difference between the temperature of the cold water leaving the tower and the air's wet-bulb temperature. The establishment of the approach fixes the operating temperature of the tower and is the most important parameter in determining both tower size and cost.

Bleed Off: is the circulating water in the tower which is discharged to waste to help keep the dissolved solids concentration of the water below a maximum allowable limit. As a result of evaporation, dissolved solids concentration will continually increase unless reduced by bleed-off.

Biocide: a chemical that is designed to control the population of troublesome microbes by killing them.

Blowdown: is the water purposely discharged from the system to control concentrations of salts or other impurities in the circulating water. Units % of circulating water rate or GPM.

British Thermal Unit (BTU): is the heat energy required to raise the temperature of one pound of water one degree Fahrenheit in the range from 32° F to 212° F

Cooling Range: is the difference in temperature between the hot water entering the tower and the cold water leaving the tower.

Cycles of Concentration: compares dissolved solids in makeup water with solids concentrated through evaporation in the circulating water. For example, chlorides are soluble in water so the cycles of concentration are equal to the ratio of chlorides in circulating water to chlorides in makeup water.

Dissolved Solids: total solids that have been dissolved into a liquid. They may be ionic and/or polar in nature.

Drift: is the water entrained in the airflow and discharged into the atmosphere. Drift loss does not include water lost by evaporation. Proper tower design can minimize drift loss.

Heat Exchanger: is a device for transferring heat from one substance to another. Heat transfer can be by direct contact, as in a cooling tower, or indirect, as in a shell and tube condenser. Can also be the tube or fin tubed bundles in a wet/dry tower.

Heat Load: The amount of heat to be removed from the circulating water within the tower. Heat load is equal to water circulation rate (GPM) times the cooling range times 500 and is expressed in BTU/hr. Heat load is also an important parameter in determining tower size and cost.

Makeup: is the amount of water required to replace normal losses caused by bleed-off, drift, and evaporation.

Pumping Head: The pressure required to pump the water from the tower basin through the entire system and return to the top of the tower.

Ton: An evaporative cooling ton is 15,000 BTU’s per hour.

Wet Bulb: is the lowest temperature that water theoretically can reach by evaporation. Wet-Bulb temperature is an extremely important parameter in tower selection and design and should be measured by a psychrometer.

To get a quote, visit our easy quote form.

From our low maintenance design to our manufacturing process to excellent customer service, we're sure you'll be pleased with our superior cooling towers, every step of the way. Get a quote